Which is Best for Your Job: A Tubing Assembly, or Pipe?

by Jeff Hopkins, on 10/10/13 8:30 AM

Don't let the thin profile fool you. For many applications tubing is simply better

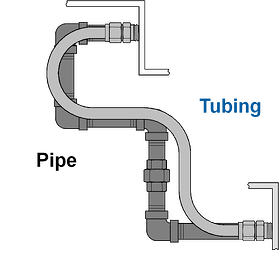

There is usually more than one way to do anything, and that includes moving fluid from Point A to Point B. Tubing will do it; so will pipe.

However, to make up the desired run using pipe, it must be cut, deburred, then threaded. All male threads must be wrapped with a PTFE tape or covered with a sealant. The pipe fittings are then tightened wrench tight.

Drawbacks to pipe

There are some inherent drawbacks with this process. First, "wrench tight" is subjective. It depends on the strength of the installer. Second, the elbows may end up being over tightened, which can damage the threads and cause leakage. Or they could be under tightened in order to line up properly and, again, result in leakage.

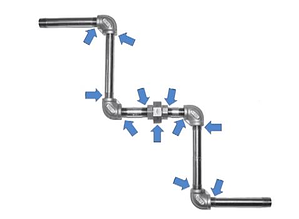

Additionally, this system has eleven potential leak points.

Once the system is installed, removal of any component requires sequential disassembly. That, in turn, may cause movement of other threaded connections and cause leaks.

Advantages of tubing

Now let's look at the same system made with tubing. First you'll notice the simplicity. All you need is a single length of tubing and two tube fittings. As with pipe, the tubing must be cut and deburred. However, to reach from Point A to Point B, the tubing is simply bent. No extra fittings are required. A bend in the tubing creates less turbulence and pressure drop than a pipe elbow.

To connect the fittings, they are pulled up a turn and a quarter manually or with the hydraulic swaging unit to create a leak-tight seal. There are only four potential leak points. Tube fittings also allow easy access to system components without sequential disassembly.

You might wonder how strong tubing is compared with pipe of the same internal size. The pipe is heavier and has a thicker wall. But the thick wall is not needed to contain system pressure. That extra material is there so that it can be cut away to create the threads.

If you build this system out of pipe, it will be much heavier. That additional weight means additional transportation and handling costs. There is more weight to store, lift and install. A heavier system puts greater strain on the supports.

Tubing, on the other hand, is sealed on its outside diameter. The wall thickness is used primarily for safe pressure containment, providing an improved strength-to-weight ratio.

Additional resources

|

|

| Swagelok® Tube Fitter's Manual | Training available from Swagelok Northern California |

Other articles

- Gaining the Swagelok® Tube Fitting Advantage

- Smart engineering make Swagelok® fittings the right choice

- Skill: Tube fitting assembly, one inch and under

/Digital%20montage%20(1).jpg?width=1920&name=Digital%20montage%20(1).jpg)